2024-1-6 02:15:34 Author: blogs.sap.com(查看原文) 阅读量:13 收藏

Hello All,

SAP IBP introduces new functions and features in every quarter of the year, coming planned releases of 2024 as (2402,2405,2408 & 2411).

SAP IBP Solutions spans over all horizons e.g Operational, Tactical & Strategic. SAP IBP Times-series solution is mostly used in the medium to long-term at higher levels like Weekly, Monthly, Quarterly, and yearly whereas SAP IBP OBP provides solutions in the Short-term horizon and at the Day, Week, and month Levels.

This blog compares Time Series(TS) & Order Based/Response Planning (OBP) Planning Engines based on the SAP IBP 2311 release.

Every customer requirement cannot be met by any single algorithm, so the Consulting Consultant should be aware of SAP IBP functionality provided by each planning Algorithm.

SAPIBP1 planning area provides Time series Planning Engines and is mainly used for Tactical Supply Planning.

Heuristic Planning Engine:

Available types:

Infinite Without Shortages: whereas it does not consider capacity and material constraints. Here all demands are fulfilled regardless of available supply.

Supply Propagation: This heuristic also creates an infinite demand and supply planning, but it propagates only the available supply downstream through the supply chain. In contrast to the supply planning heuristic, it does not fulfill all demands if there is insufficient supply/. The resulting plan allows the planner to see the impact of the supply problem, that is, which customer demands and net demands of which customer products and location products will not be met.

Note: As of SAP IBP for Supply Chain 2005, the time-series-based supply propagation heuristic is no longer available for customers on newly installed SAP IBP systems.

Shelf Life Planning: This heuristic considers the shelf life of products when creating a supply plan. It behaves in a similar way to the infinite without shortages supply planning heuristic and performs infinite demand and supply planning with no shortages.

Shelf Life Distribution Planning This heuristic considers the shelf life of products when creating a supply plan. It behaves similarly to the shelf life planning heuristic, but it only distributes the available supply downstream through the supply chain. It doesn’t fulfill all demands if there is insufficient supply. The resulting plan allows you to see the impact of any supply problems, showing the demands for customer and location products that won’t be met, taking shelf life into account.

Finite Heuristic – This algorithm creates a priority-based finite supply plan in which demands are fulfilled depending on available supply

Optimizer Planning Engine:

Available modes: Profit Maximization and Delivery Maximization

Optimizer – This algorithm creates a finite cost-optimized supply plan considering capacities and material constraints.

The time-series-based supply planning optimizer maximizes profit or deliveries, depending on how it is configured. It creates a cost-optimized production, distribution, and procurement plan for the entire supply chain network taking into account constraints. Optimization is performed by transforming the supply planning problem into a mathematical model, that is, a mixed integer linear program (MILP).

Note: Green color represents the functionality supported, Yellow color represents the functionality supported but not completely, and White color Represents the Functionality not supported.

Time-Series Planning Engines Functionalities Image1

Time-Series Planning Engines Functionalities Image2

Time-Series Planning Engines Functionalities Image3

SAP7F Planning area provides Order-Based Planning Engines and mainly used for Operational Supply Planning.

Order-Based Planning: Supply Planning Run

Supply planning Run:

The planning looks at the open order quantity of sales orders, at fixed demands and receipts, forecast demands (considering their consumption by sales orders), and buffer stock. Supply planning takes record of fulfilled and unfulfilled sales orders and of sales orders fulfilled late and provides the corresponding key figure values. If you activate the corresponding option in the planning run profile, it also takes record of forecast quantities that are fulfilled in time or late.

Supply planning with allocation creation

The planning looks at forecast demands and fixed demands and receipts, taking record of fulfilled and unfulfilled forecasts and of forecasts fulfilled late. It also considers buffer stock. The planning does not consider sales orders or forecast consumption. It calculates constrained forecast key figure values.

Supply planning with order confirmation

The planning looks at the open order quantity of sales orders, at fixed demands and receipts, forecast demands (considering their consumption by sales orders) and buffer stock. It takes record of fulfilled and unfulfilled sales orders and of sales orders fulfilled late and provides corresponding key figure values. If you activate the corresponding option in the planning run profile, it also takes record of forecast quantities that are fulfilled in time or late. The focus of this planning process is to create order confirmations (including gating factors), based on the order network.

OBP Supply Run

Order-Based Planning: Deployment Run

You can schedule this job to distribute supply over the supply network of your organization, given its priorities and available-to-deploy elements. If you choose the optimizer planning algorithm, cost parameters, except for production and procurement, and additional constraints, such as maximum lateness are considered.

Order-Based Planning: DDR Run

You can schedule this job to perform planning within the demand-driven replenishment process. Considering decoupling points with average daily usages (ADUs) and buffer sizes as an input, the Order-Based Planning: DDR Run creates supply elements to ensure the flow in decoupling points and calculates the replenishment quantity and date. The key driver in determining the need for a new replenishment element at a decoupling point is the net flow position.

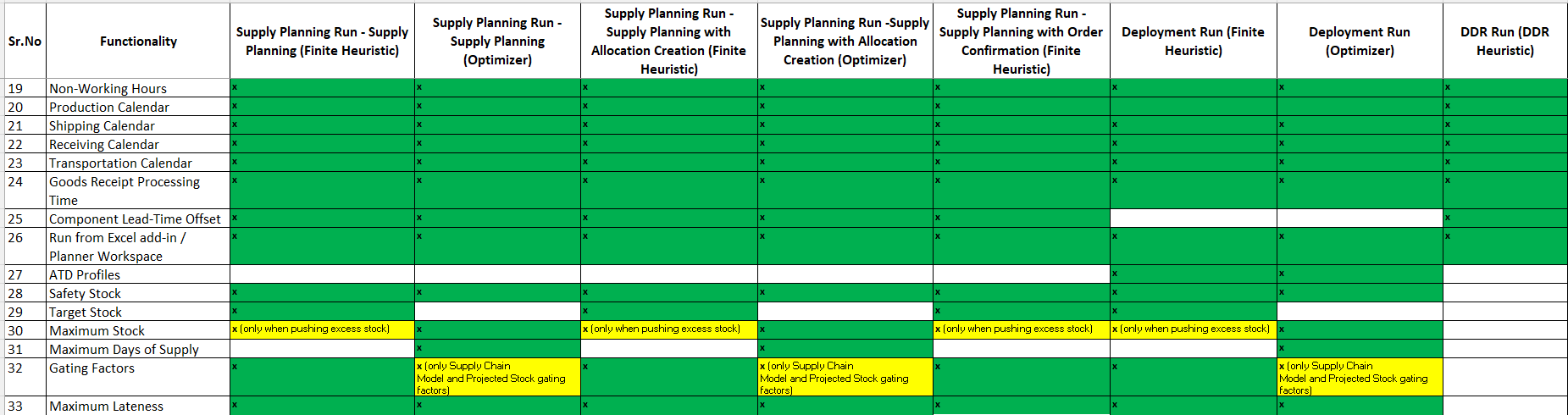

Note: Green color represents the functionality supported, Yellow color represents the functionality supported but not completely, and White color Represents the Functionality not supported.

Order-Based Planning Engines Functionalities Image1

Order-Based Planning Engines Functionalities Image2

Order-Based Planning Engines Functionalities Image3

Order-Based Planning Engines Functionalities Image4

References:

https://help.sap.com/docs/SAP_INTEGRATED_BUSINESS_PLANNING?locale=en-US&task=whats_new_task

https://help.sap.com/docs/SAP_INTEGRATED_BUSINESS_PLANNING/feae3cea3cc549aaa9d9de7d363a83e6/e5593253b1e44058beea284fadc8b4c2.html?locale=en-US

Kind Regards,

Pravin Tikar

如有侵权请联系:admin#unsafe.sh